The Ultimate Guide to PCB Fabrication: Navigating the 2023 Industry Landscape and Beyond

As we navigate the complexities of the electronics industry in 2023, the significance of efficient and innovative PCB fabrication cannot be overstated. According to a recent report by Research and Markets, the global PCB market is expected to reach USD 82.3 billion by 2026, experiencing a compound annual growth rate (CAGR) of 4.85% from 2021. This booming growth underlines the urgency for manufacturers to explore diverse alternatives in PCB fabrication that enhance performance and reduce costs. Various techniques and technologies are emerging, shifting the paradigms of traditional fabrication methods. This guide delves into the essential alternatives available in PCB fabrication today, equipping industry professionals with insights to adapt and thrive in an ever-evolving landscape, ensuring a competitive edge in their ventures.

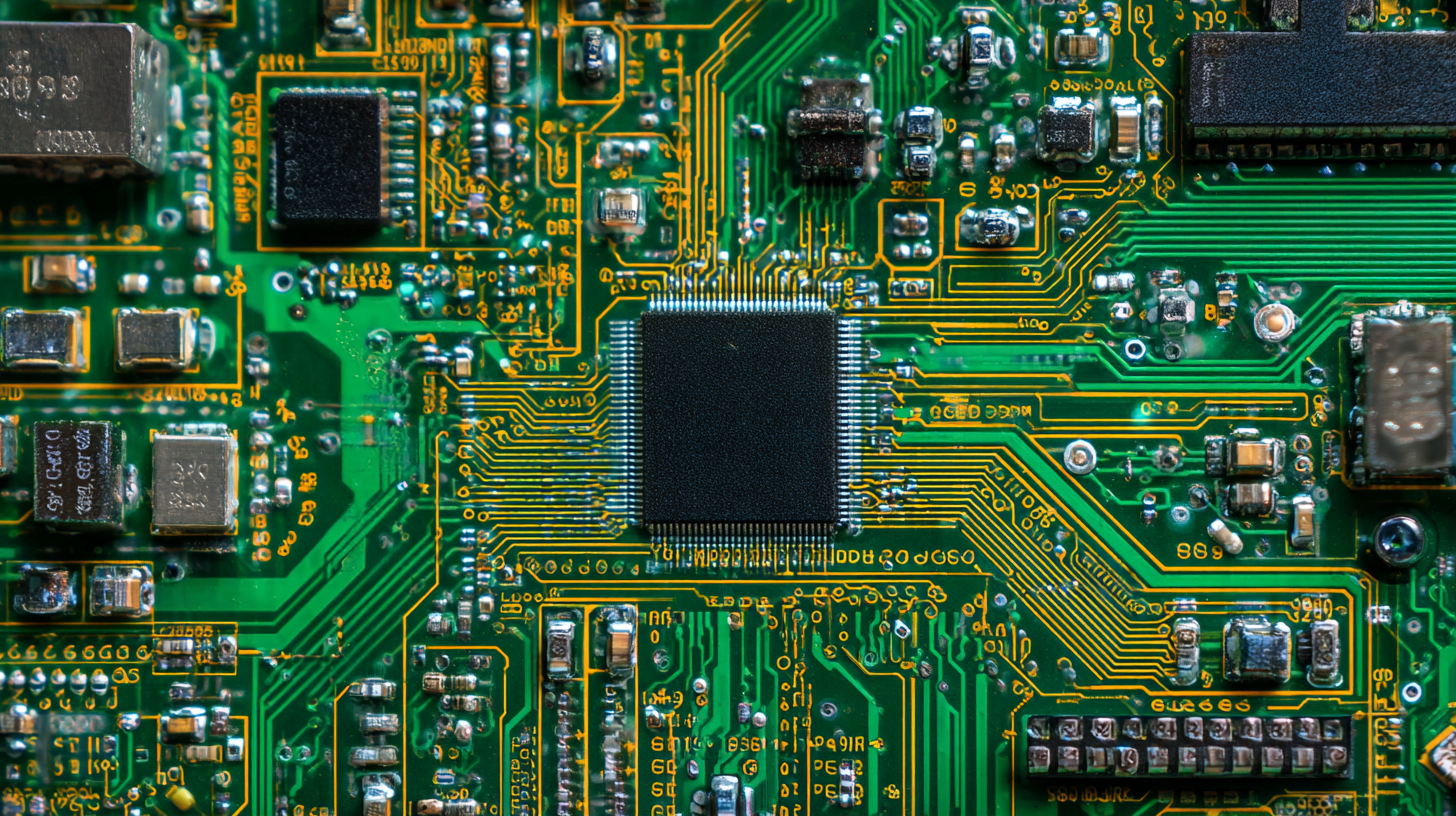

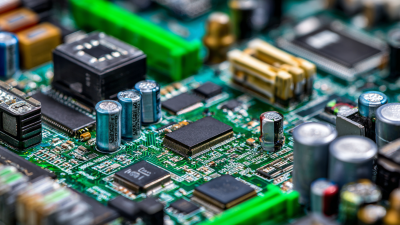

Understanding the Basics of PCB Fabrication: Materials and Processes Explained

Understanding the basics of PCB fabrication is crucial for anyone entering the electronics industry. According to a report by Research and Markets, the global PCB market is projected to reach $80 billion by 2024, driven by the rising demand for advanced electronics across various sectors. The fabrication process begins with choosing the right materials, which can significantly affect the performance and reliability of the final product. Typically, FR-4 epoxy laminate is the most commonly used substrate due to its excellent electrical insulation and thermal properties.

In addition to materials, the PCB fabrication process itself involves various critical steps, including etching, drilling, and lamination. A recent industry study highlighted that more than 60% of defects in PCBs originate during the etching phase, emphasizing the need for precise control and quality assurance. Furthermore, advancements in technology, such as the adoption of automated systems and the use of cloud-based design tools, are transforming how fabricated PCBs are designed and manufactured. This evolution is not only enhancing efficiency but also pushing manufacturers to maintain higher standards in production, aligning with trends in miniaturization and increased functionality in electronic devices.

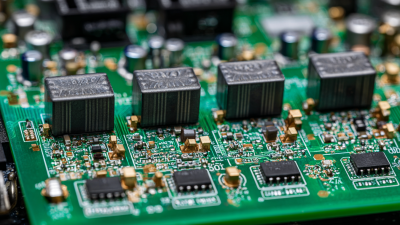

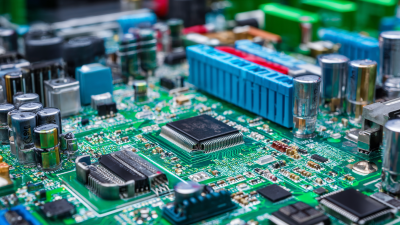

Emerging Technologies in PCB Manufacturing: Trends to Watch for in 2023

In 2023, the PCB manufacturing industry is undergoing a significant transformation, driven by emerging technologies that promise to enhance efficiency and reduce costs. One of the most compelling trends is the rise of advanced materials such as flexible and printed electronics. According to a report by IPC, the flexible PCB market is expected to reach $25 billion by 2025, reflecting a compound annual growth rate of over 9%. This shift allows manufacturers to create more versatile designs, catering to applications in wearables, smartphones, and IoT devices.

Another critical trend is the integration of automation and artificial intelligence in PCB fabrication processes. According to a study by Technavio, the global smart manufacturing market will grow by $248 billion from 2022 to 2026, significantly affecting PCB production. Automation not only enhances precision but also reduces manufacturing time. Additionally, AI-powered quality control systems are increasingly being utilized, leading to a reduction in defects and improved overall yield rates. As manufacturers adopt these innovations, they position themselves to meet the growing demand for more complex and reliable electronic components in the coming years.

Sustainability in PCB Fabrication: Eco-Friendly Practices and Innovations

Sustainability in PCB fabrication has emerged as a critical focus for the electronics industry, driven by increasing environmental regulations and consumer demand for greener products. According to a 2022 report by the International Electronics Manufacturing Initiative (iNEMI), the electronics waste generation is projected to reach 74 million metric tons by 2030. This alarming trend has prompted many PCB manufacturers to adopt eco-friendly practices, such as the use of lead-free materials and processes that minimize energy consumption.

Innovations such as bio-based substrates and environmentally friendly etching techniques are leading the charge in sustainable PCB manufacturing. A survey conducted by the IPC in 2023 revealed that over 60% of PCB manufacturers are investing in green technologies, aiming to reduce their carbon footprint by at least 25% within the next five years. Additionally, companies are increasingly embracing closed-loop processes that enable waste materials to be recycled and reused, thus significantly reducing landfill contributions. As the industry evolves, these sustainable practices not only help in compliance with regulations but also enhance the reputation of manufacturers in a market that is progressively favoring eco-conscious businesses.

Cost Factors in PCB Production: Strategies for Budget Management and Efficiency

When it comes to PCB production, understanding cost factors is crucial for effective budget management. The primary components influencing costs include raw materials, manufacturing techniques, and labor expenses. High-quality materials, while potentially expensive, can enhance the performance and durability of the final product. It’s essential for companies to strike a balance between quality and cost by sourcing reliable suppliers and exploring alternative materials that can reduce expenses without compromising on function.

Efficiency in PCB production not only helps in controlling costs but also streamlines the entire manufacturing process. Implementing strategies such as lean manufacturing and automation can significantly reduce waste and enhance production speed. Moreover, conducting a thorough cost analysis to identify inefficiencies or overages is vital. By leveraging advanced software tools for design and production planning, companies can optimize layouts and minimize errors, ultimately leading to a more cost-effective and efficient PCB fabrication process. These strategic approaches are essential for staying competitive in the rapidly evolving electronics market of 2023 and beyond.

Future-Proofing Your PCB Designs: Best Practices for Long-Term Viability

In today’s rapidly evolving electronics market, future-proofing your PCB designs is essential for long-term viability. Designers should consider scalability as a critical factor; choosing components that are widely available and have a long product lifecycle ensures that your designs can adapt to changing technologies. Furthermore, modular designs that allow for easy upgrades or replacements can be a game-changer in extending the lifespan of your products. By anticipating market trends and customer needs, you can create PCBs that remain relevant, eliminating the need for costly redesigns.

Another best practice is to incorporate sustainability into your PCB design process. Using eco-friendly materials and adhering to industry standards can not only appeal to environmentally-conscious consumers but also promote compliance with impending regulations. Additionally, ensuring your designs are compatible with various manufacturing processes can enhance flexibility and reduce risks associated with supply chain disruptions. Emphasizing durability and reducing the number of layers in your PCB can also lead to cost savings while maintaining performance. By integrating these strategies, you can significantly enhance the longevity and reliability of your PCB designs in an ever-changing landscape.

Related Posts

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Essential Checklist for Choosing the Best PCB Fabrication Services Based on Industry Standards

-

Ultimate Checklist for Selecting the Best PCB Fabrication Services Worldwide

-

Emerging Trends in Circuit Board Design for 2025: Innovating for the Future

-

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals

-

Navigating Import Export Certifications for Best Electronic Board Assembly Suppliers