Understanding the Innovations Behind Flexible Circuit Boards in Modern Electronics

The advent of flexible circuit boards has revolutionized the

electronics industry, enabling the design of

lighter, more compact, and efficient devices. As per a report by

IDTechEx, the global market for flexible printed circuit boards (FPCBs) is projected to reach

$16.4 billion by 2023, growing at a compound annual growth rate

(CAGR) of 10% from 2018 to 2023. This growth is driven by the increasing demand for

miniaturization in consumer electronics, automotive applications, and medical devices.

Flexible circuit boards are not only critical in enhancing the

performance and reliability of electronic components but also

facilitate innovative designs that were previously unattainable with traditional rigid boards.

As industries continue to prioritize adaptability and

lightweight solutions, understanding the innovations behind flexible

circuit boards becomes essential for engineers and

designers looking to stay at the forefront of modern electronics.

Flexible circuit boards are not only critical in enhancing the

performance and reliability of electronic components but also

facilitate innovative designs that were previously unattainable with traditional rigid boards.

As industries continue to prioritize adaptability and

lightweight solutions, understanding the innovations behind flexible

circuit boards becomes essential for engineers and

designers looking to stay at the forefront of modern electronics.

Understanding the Basics of Flexible Circuit Boards in Modern Electronics

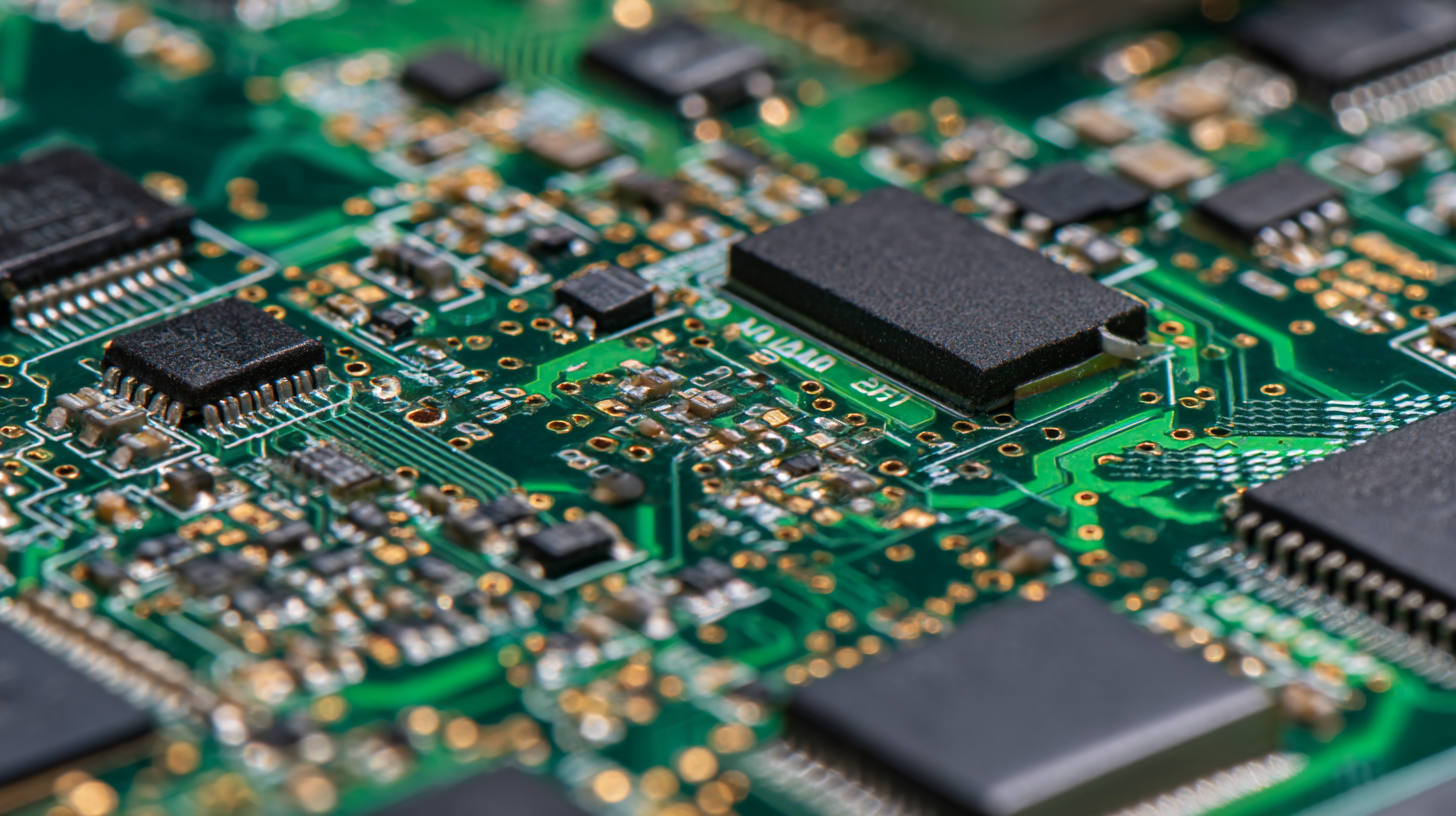

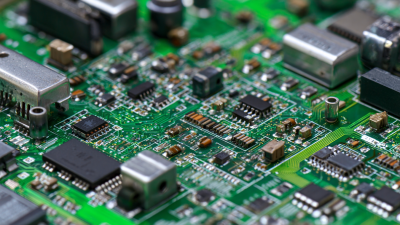

Flexible circuit boards, or flex PCBs, are a key innovation in modern electronics, allowing for more compact designs and versatile applications. Unlike traditional rigid circuit boards, flexible circuits can bend, twist, and fit into various shapes without losing functionality. This flexibility enables engineers to create smaller devices with complex internal structures, catering to the growing demand for portable and lightweight products across numerous industries, including consumer electronics, automotive, and medical technology.

The construction of flexible circuit boards typically involves thin layers of conductive materials, such as copper, laminated onto a flexible substrate. This design not only reduces the overall weight of the electronic device but also enhances its durability by minimizing potential fracture points that rigid boards might encounter. Additionally, advancements in materials and manufacturing techniques have made it possible for flex PCBs to support high-density interconnections, increasing functionality without compromising performance. As a result, flexible circuits are increasingly being integrated into innovative devices, paving the way for the next generation of electronic applications.

Exploring the Key Materials Used in Flexible Circuit Board Production

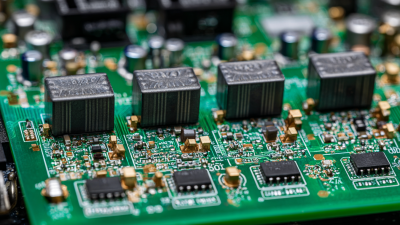

The evolution of flexible circuit boards (PCBs) is closely tied to advancements in key materials that enhance their performance and applications. These boards are typically composed of materials such as polyimide, which offers excellent thermal stability and flexibility. Innovations like transparent PCBs are paving the way for breakthroughs in medical devices and consumer electronics, enabling innovative designs that were previously unattainable.

As the demand for miniaturization and enhanced functionalities grows, the flexible printed circuit board market is expanding rapidly. The integration of advanced materials helps create ultra-thin designs that maintain reliability and performance. For manufacturers, staying abreast of these material advancements is crucial to meet the expectations of modern electronics, particularly as technologies like 5G are adopted.

**Tip 1:** When selecting materials for flexible circuit production, evaluate thermal stability and flexibility to ensure optimal performance in various applications.

**Tip 2:** Keep an eye on the latest developments in manufacturing techniques, such as 3D printing, which can provide unique advantages in creating micro and nano devices.

**Tip 3:** Consider sustainability in material choices to address environmental impacts, as innovations in eco-friendly manufacturing processes are becoming increasingly important.

Understanding the Innovations Behind Flexible Circuit Boards in Modern Electronics

| Material | Properties | Applications | Advantages |

|---|---|---|---|

| Polyimide Film | High temperature resistance, excellent electrical insulation | Aerospace, automotive, consumer electronics | Durability, flexibility, lightweight |

| Copper Foil | High conductivity, malleability | Phone flex circuits, wearable devices | Efficient power transmission, lightweight |

| Laminates | Good dielectric properties, thermal stability | Medical devices, automotive parts | Low moisture absorption, dimensional stability |

| Surface Finish (ENIG) | Corrosion resistance, excellent solderability | High-density connectors, RF applications | Long shelf life, reliable connections |

| Adhesives | Strong bonding, thermal stability | Flex circuits assembly, multi-layer boards | Improves structural integrity, reduces weight |

Examining the Manufacturing Process of Flexible Circuit Boards

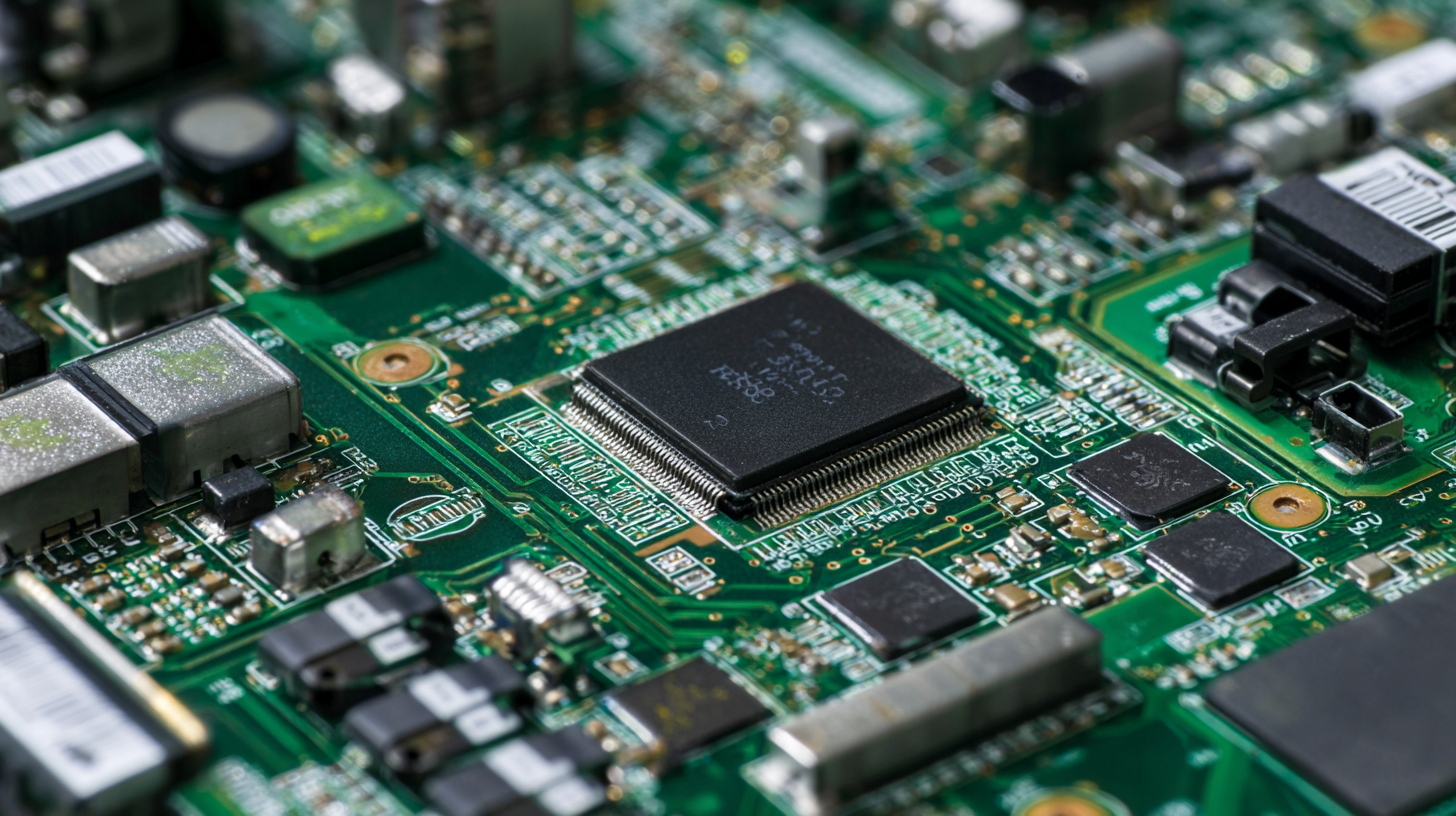

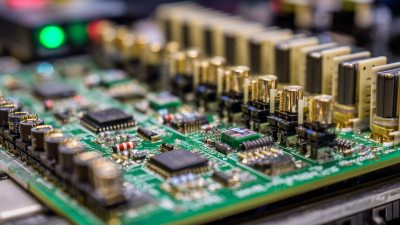

The manufacturing process of flexible circuit boards involves several key stages that ensure their functionality and durability. Initially, the design phase incorporates computer-aided design (CAD) software to create intricate layouts that accommodate the specific requirements of modern electronics. This phase is crucial, as it defines the electrical pathways and component placements on the flexible substrate. Following the design, materials such as polyimide or polyester are chosen for their excellent thermal and electrical properties, enabling the board to bend and flex without compromising performance.

The manufacturing process of flexible circuit boards involves several key stages that ensure their functionality and durability. Initially, the design phase incorporates computer-aided design (CAD) software to create intricate layouts that accommodate the specific requirements of modern electronics. This phase is crucial, as it defines the electrical pathways and component placements on the flexible substrate. Following the design, materials such as polyimide or polyester are chosen for their excellent thermal and electrical properties, enabling the board to bend and flex without compromising performance.

One important tip during the manufacturing process is to maintain a clean workspace to prevent contamination of the materials. Any foreign particles can negatively affect the quality of the final product. Additionally, when applying adhesive layers, ensure even distribution to facilitate a stronger bond between the layers, enhancing the overall integrity of the flexible circuit board.

Once the materials are prepared, the next step involves the application of circuit patterns. This is typically done through techniques like screen printing or etching. The final assembly involves integrating electronic components, where precise placement and soldering techniques come into play. Thorough testing follows, ensuring that the flexible circuit boards meet the stringent demands of today’s electronic devices, from smartphones to wearable technology.

Applications of Flexible Circuit Boards in Consumer Electronics and Beyond

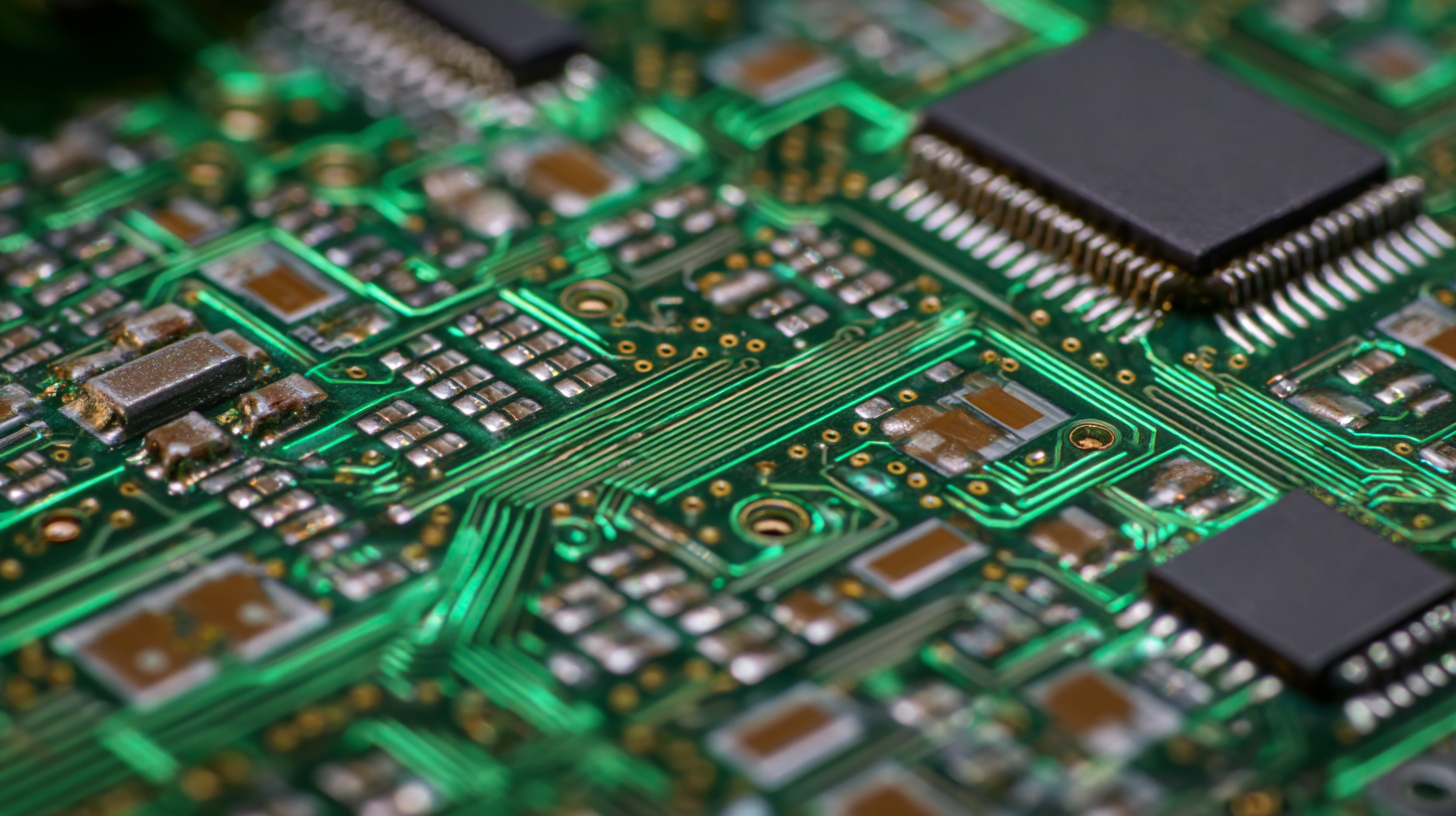

Flexible circuit boards have revolutionized the landscape of consumer electronics by allowing manufacturers to create compact, lightweight, and highly functional devices. These circuits find application in everything from smartphones and tablets to wearables like smartwatches and fitness trackers. Their ability to bend, twist, and conform to various shapes enables innovative designs that enhance user experience. As technology continues to evolve, flexible circuits are also penetrating industries such as automotive and healthcare, proving that their versatility extends far beyond consumer electronics.

Tip: When considering incorporating flexible circuit boards into your design, be mindful of the materials used. High-quality substrates not only improve performance but also increase longevity, ensuring that your devices retain their functionality through daily use.

The application of flexible circuit boards in consumer electronics facilitates the development of multi-layered circuits that can achieve complex tasks while minimizing space. This innovation is particularly beneficial in the fast-paced tech industry, where smaller and lighter devices are in high demand. Beyond consumer electronics, flexible circuits are increasingly being used in medical devices, such as flexible sensors and diagnostic equipment, where adapting to various shapes and surfaces is crucial for effective functionality.

Tip: Keep an eye on emerging trends in flexible circuit technology, as advancements in manufacturing techniques can lead to cost-effective solutions, making it feasible for startups and small businesses to leverage these innovations in their product development.

The Future Trends and Innovations in Flexible Circuit Board Technology

The realm of flexible circuit board technology is rapidly evolving, driven by the need for compact and efficient electronic devices. Future trends indicate a significant shift towards enhanced materials and manufacturing processes, allowing for more intricate designs and improved conductivity. As applications in consumer electronics, medical devices, and automotive systems expand, the demand for lighter and more adaptable circuit solutions will only grow.

Tips for integrating flexible circuit boards into your designs include focusing on materials that offer durability yet maintain flexibility. Additionally, leveraging advanced simulation tools can aid in optimizing design parameters early in the development process. Consider also the potential of hybrid circuits, which combine traditional rigid boards with flexible technology, to meet diverse application requirements.

Innovations such as printed electronics and 3D circuit structures are paving the way for new functionalities and efficiency in flexible circuit boards. Embracing these advancements will allow designers to create more sophisticated devices that can withstand the rigors of modern usage while maintaining performance and reliability in various environments.

Related Posts

-

Ultimate Guide to Flex PCB Manufacturing for Innovative Solutions

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Ultimate Checklist for Selecting the Best PCB Fabrication Services Worldwide

-

Essential Checklist for Choosing the Best PCB Fabrication Services Based on Industry Standards

-

The Ultimate Guide to Mastering Circuit Board Assembly Techniques for Success

-

How to Achieve High Quality in Electronic Board Assembly Process