How to Achieve High Quality in Electronic Board Assembly Process

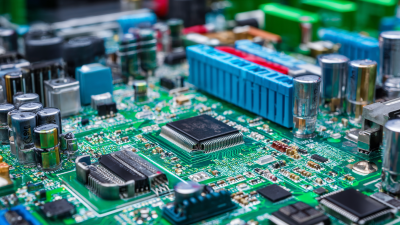

In the rapidly evolving field of electronics manufacturing, achieving high quality in the electronic board assembly process has become paramount for ensuring the reliability and performance of electronic devices. According to a recent report by IPC, the global standard development organization for the electronics industry, over 70% of defects in electronic products can be traced back to issues in the assembly phase, highlighting the critical need for robust quality control measures.

Furthermore, a study by the Electronics Industry Association estimates that poor assembly practices can lead to increased costs of up to 30% due to rework and customer returns. As the demand for sophisticated electronic products continues to rise, manufacturers must implement best practices in electronic board assembly to enhance product quality, reduce production costs, and ensure customer satisfaction.

This article delves into effective strategies to optimize the electronic board assembly process and achieve exceptional quality standards.

Understanding the Importance of Quality Standards in Electronic Board Assembly

In the realm of electronic board assembly, maintaining high-quality standards is paramount. Quality assurance not only ensures the reliability and performance of the final products but also minimizes defects and reduces costly rework. As the complexity of electronic assemblies increases, understanding the significance of these standards becomes crucial for manufacturers aiming to compete in a rapidly evolving market. Establishing robust quality benchmarks helps in aligning production processes with industry expectations, ultimately leading to enhanced customer satisfaction.

With the rise of automation technologies, such as humanoid robots integrated into assembly processes, the importance of quality standards is further accentuated. These advanced systems can streamline production while adhering to precise specifications, thus enhancing overall efficiency. As manufacturers adopt intelligent automation, they must ensure that their quality control measures are robust enough to keep pace with the innovations in technology.

This convergence of automation and stringent quality standards promises a future where electronic board assembly is not only more efficient but also significantly more reliable.

Key Steps for Selecting the Right Materials and Components

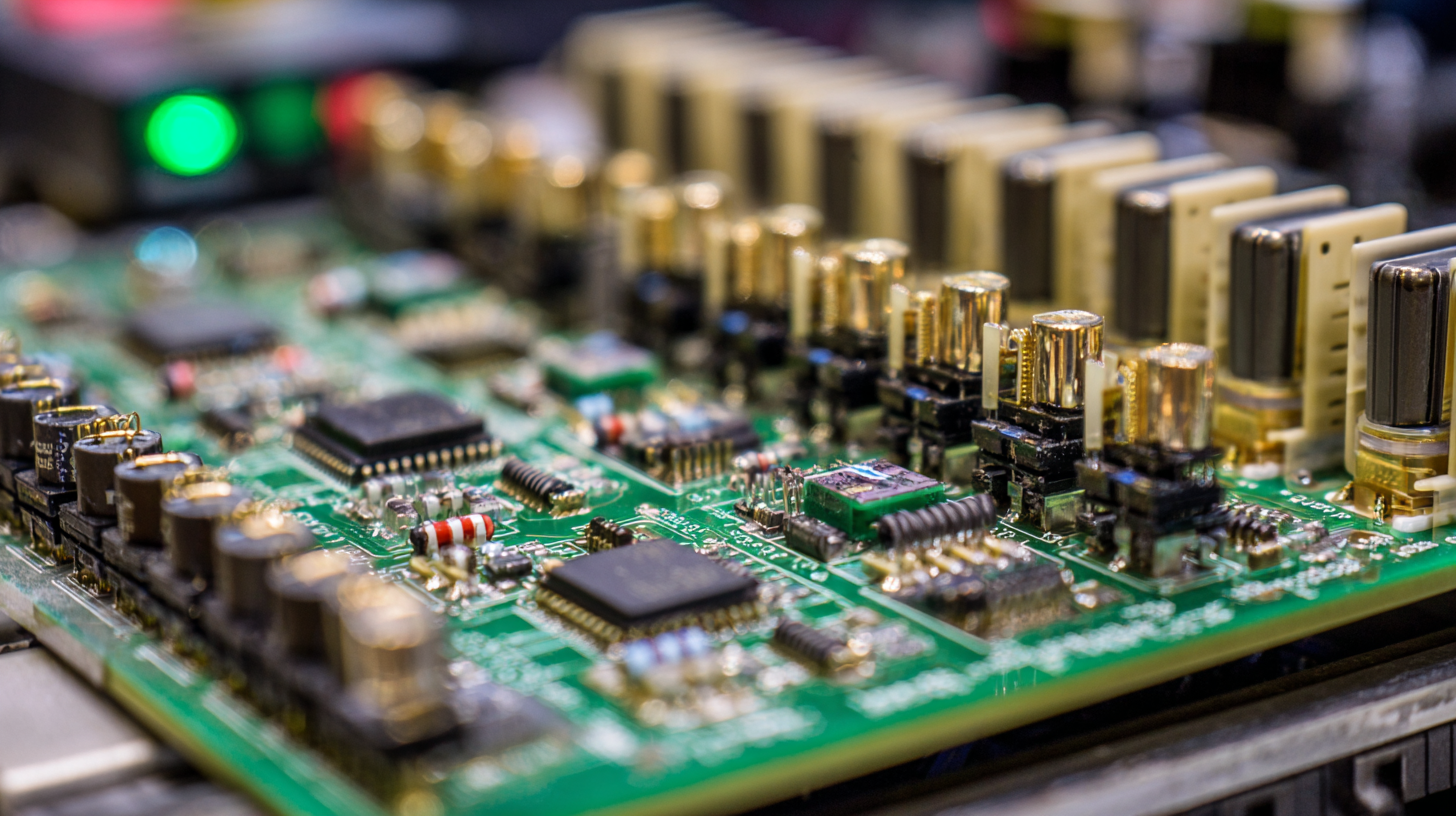

Selecting the right materials and components is crucial for achieving high quality in the electronic board assembly process. The first step involves understanding the specific requirements of the project, which include operational environments, regulatory standards, and long-term reliability. Choosing materials that are compatible with the intended application ensures the final product will perform optimally. For instance, selecting suitable substrates and solder types can prevent issues such as thermal stress and corrosion, which often compromise the assembly's integrity.

Additionally, sourcing high-quality components from reputable suppliers is essential. This not only influences the performance of the assembled boards but also affects their longevity. Incorporating components with proven reliability ratings can mitigate failure rates and enhance durability. It’s also important to evaluate the components for compatibility with other elements in the assembly process. By conducting thorough testing and validation of both materials and components, manufacturers can significantly improve the quality of their electronic boards and avoid costly reworks in the future.

How to Achieve High Quality in Electronic Board Assembly Process - Key Steps for Selecting the Right Materials and Components

| Component Type | Material | Quality Rating | Supplier Reliability | Cost ($) |

|---|---|---|---|---|

| Resistor | Carbon Film | A | High | 0.10 |

| Capacitor | Ceramic | A+ | Medium | 0.50 |

| Inductor | Ferrite Core | B+ | High | 1.20 |

| Microcontroller | Silicon | A | High | 3.00 |

| Diode | Silicon | A | Medium | 0.25 |

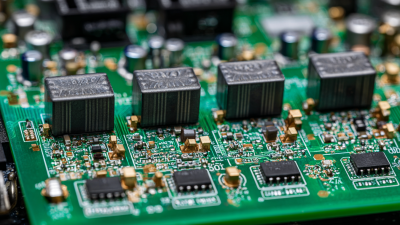

Effective Techniques for Soldering and Assembly Processes

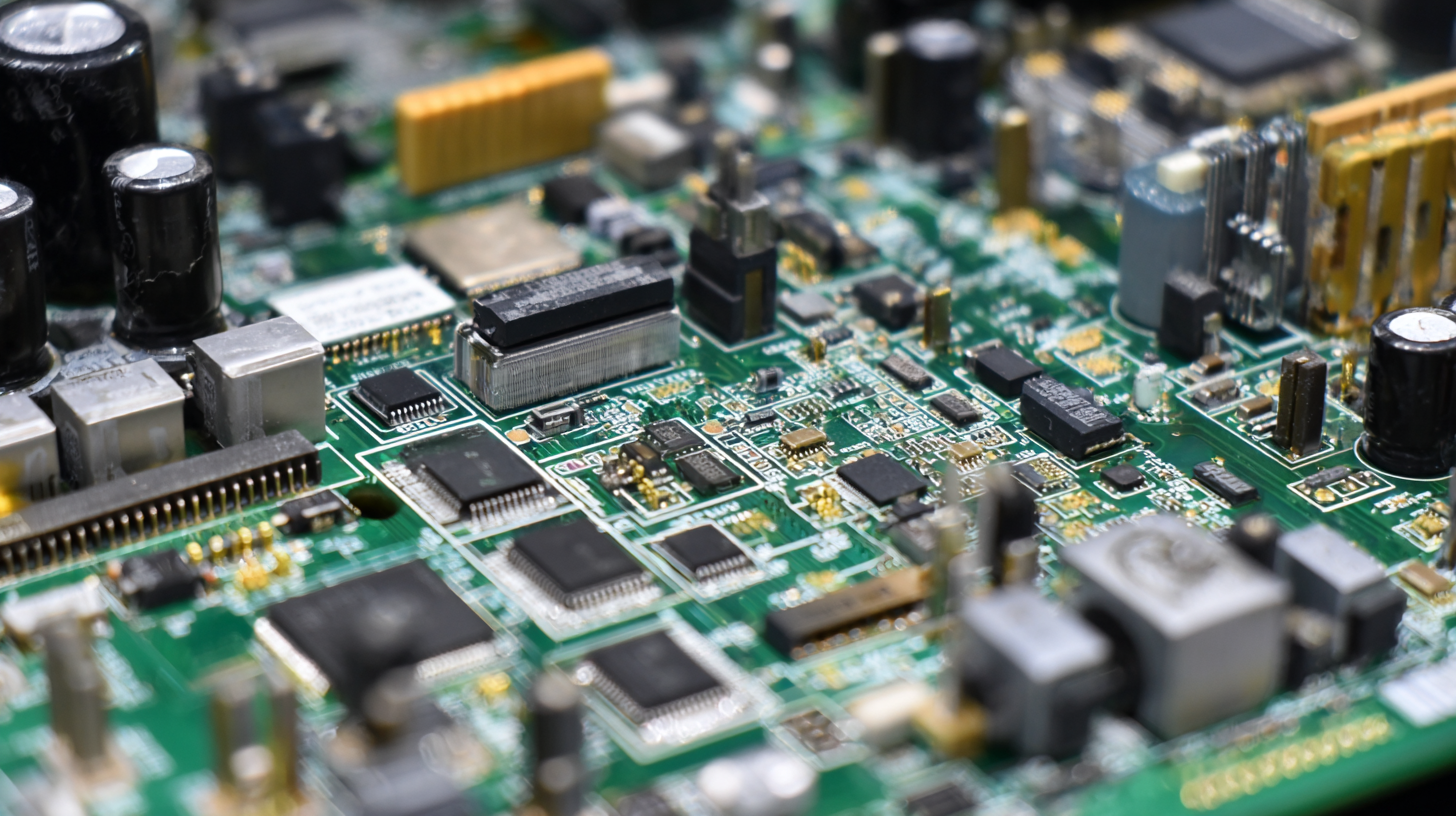

The soldering and assembly processes in electronic board assembly are critical to achieving high-quality outcomes. According to a recent IPC report, over 70% of assembly defects stem from poor solder joint quality, underscoring the necessity for rigorous techniques. One effective technique is the use of controlled solder paste deposition, which ensures an even application and minimizes defects such as solder bridges. Implementing automated stencil fabrication can improve consistency in solder paste thickness, driving down the failure rate during reflow.

Another pivotal aspect is the temperature control during the soldering process. Data from the SMT Magazine indicates that proper thermal profiling can reduce the risk of thermal shock, which affects component reliability. Utilizing infrared heating systems enables precise temperature adjustments, facilitating smoother transitions during soldering. Moreover, investing in high-quality solder materials can significantly enhance joint integrity; industry studies show that lead-free solders, when properly formulated, offer improved mechanical performance compared to traditional solders. By adopting these advanced techniques, manufacturers can enhance the reliability and performance of electronic assemblies, ultimately leading to greater customer satisfaction.

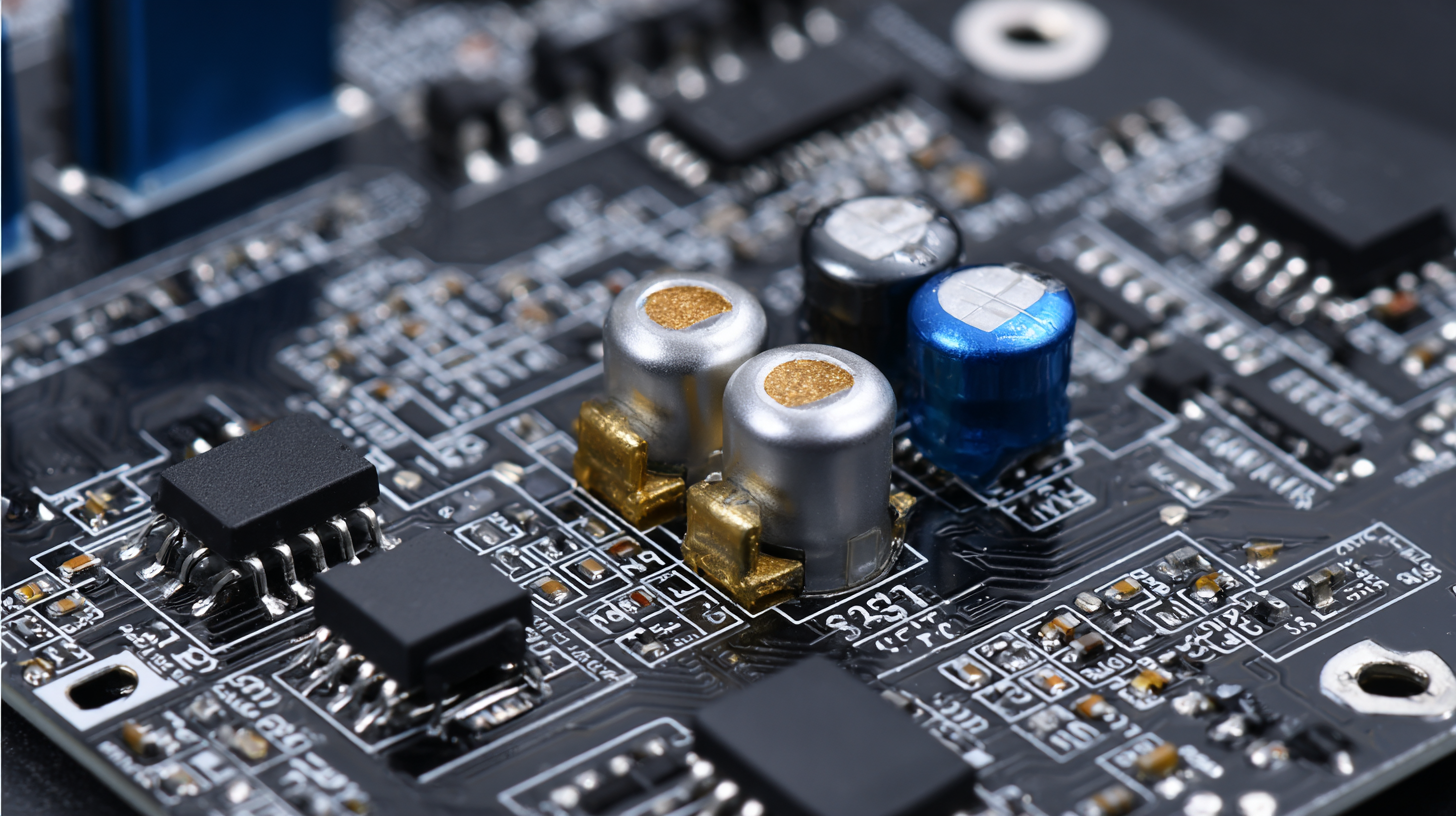

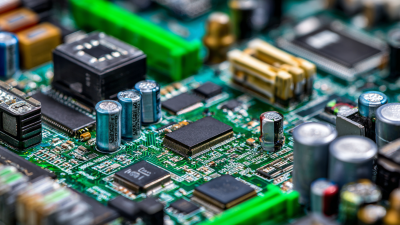

Implementing Quality Control Measures Throughout Production

In the electronic board assembly process, implementing effective quality control measures is essential to ensure high standards are met throughout production. Quality control not only minimizes defects but also enhances overall efficiency, leading to increased customer satisfaction. One of the best methods to achieve this is by integrating inspection points at various stages of assembly. By performing checks after critical processes such as soldering and component placement, manufacturers can quickly identify and correct errors before they escalate.

Tips: Establishing a standardized inspection checklist can streamline this process. Ensure that all team members are trained to utilize the checklist effectively, identifying common issues and fostering a culture of accountability. Regular training sessions can keep your team updated on the latest quality standards and techniques.

Additionally, leveraging automation in the quality control process can greatly improve accuracy and consistency. Automated visual inspection systems can detect defects that might be missed by the human eye. Investing in such technology not only saves labor costs but also increases the reliability of quality checks.

Tips: When selecting automated systems, consider the specific needs of your production line and ensure compatibility with existing equipment to maximize efficiency.

Training and Skill Development for Technicians in PCB Assembly

To achieve high-quality electronic board assembly, training and skill development for technicians play a crucial role. As technology in the electronics sector evolves rapidly, the need for a skilled workforce becomes more apparent. Innovative skill development programs tailored for emerging technologies are essential to address the current and future demands of the market. Institutes focused on electronics, like the Electronics Sector Skills Council of India, are vital in bridging the skill gap through specialized training sessions, workshops, and certifications that prepare technicians for the complexities of PCB assembly.

Moreover, initiatives such as the 'School of Semiconductor' in Tamil Nadu aim to cultivate a robust workforce equipped with the necessary skills to thrive in the semiconductor industry. These programs not only enhance the technical abilities of workers but also instill a sense of adaptability in navigating technological advancements. By investing in training and skill development, companies can ensure that their technicians remain competitive, ultimately leading to improved quality and efficiency in the electronic board assembly process.

Training Investment and Skill Development in PCB Assembly

This chart represents the investment allocated towards various training programs to improve the skills of technicians in the PCB assembly process. Each category highlights a critical aspect of technician competencies that directly impact the quality of electronic board assembly.

Related Posts

-

Essential Tips for Identifying Top-Quality PCB Assembly Manufacturers

-

Navigating Import Export Certifications for Best Electronic Board Assembly Suppliers

-

The Ultimate Guide to Mastering Circuit Board Assembly Techniques for Success

-

Emerging Trends in Circuit Board Design for 2025: Innovating for the Future

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals